Continuous Asphalt Plant drum mix asphalt mixing equipment

Brand: BituRock

Product origin: WUXI, JIANGSU,CHINA

Delivery time: 30-40 DAYS

Supply capacity: 5 SETS PER MONTH

EQUIPMENT CHARACTERESTICS

Cold Feeding System

Convenient, efficient and stable

Two groups of independent cold aggregate hoppers. With mesh screen for oversize materials; frequency belt feeders; vibrators fixed in sand material hoppers; no-material detection and alarm devices are set to timely inform the feeding through transmission signals and alarm lights.

Drying System

Optimized design, energy conservation, high efficiency

Reasonable drum heating zone and material lifting devices arrangement greatly increase drying heating efficiency and reduce fuel consumption.

The dryer drum is made of boiler plate, rockwoll insulation and covered by stainless steel. Friction driven, with automatic lubrication system and negative pressure detection device. The infrared thermometer can accurately monitor the temperature ( ±5 °C ).

The burner is special for Asphalt Mixing Plant, PID auto double frequency conversion control. With heavy oil preheating system, realize diesel oil and heavy oil use. Through compressed air atomizing combustion flame, more energy-saving.

Vibration screen

Maintenance-free, high accuracy, stable

Adopt maintenance-free vibration motors, meshes easy fix and dismantle. Mesh size can be customized.

Integral optimal structure, best performance, realizes the efficient screening and ensures accurate gradation.

Mixer

Batch mixing, high efficiency, top mixture quality

Two-shaft forced batch mixing. Bitumen sprayed into mixer through bitumen pumps, which enables bitumen uniformly attached on aggregate. The hot mixture product is high quality.

The mixer insulated with thermic oil which enables to many additives, like SMA, warm mixing, foam bitumen, etc.

Dust Collection System

Environmental protection, efficient and safety

The optimal combination of Gravity dust collector + bag filter. Collected dust from primary dust collector conveyed into aggregate elevator. While dust from filter bag is conveyed into reclaimed filler bin.

Filter bag is made of Nomex product. The max. instant temperature resistance is 250℃.

Temperature control system, over-limit ceasefire device and cold air valve to make sure the safety of the filter bags.

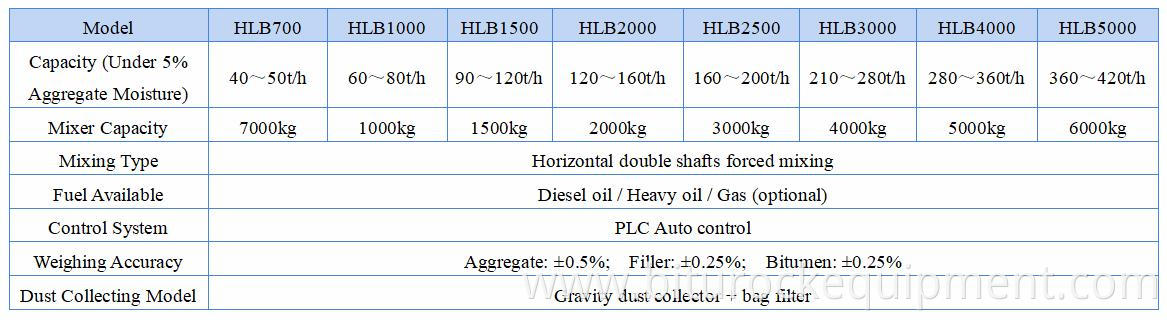

Control System

Full-auto control, easy operation, safe and reliable

Double computer control with PLC, full-automatic and manual control switchable, easy to operate. With fault alarm and analysis, real-time monitoring and online service, the system is more reliable. Main electric elements adopt world-renowned brands, such as Siemens, Schneider,Omron, etc. The computer interface dynamically displays the whole production process flow and timely alarm.